- Our Models

- ServicesHesitant in service?

Get in touch with us with your business problem and we’ll consult you on the suitable service solution.

- SolutionsApplicationsLegacy SupportOther Microsoft SolutionsPower Platform ConsultantsAzure ConsultantsAzure Developers

- Industries

- Our Company

About Us

About UsLearn more about our HireDynamicsDevelopers portal and the team behind it.

Case StudiesRead successful stories from our clients across various industries.

ServicesFind the right service according to your specific business needs.

- Resources

- Our Models

- ServicesHesitant in service?

Get in touch with us with your business problem and we’ll consult you on the suitable service solution.

- SolutionsApplicationsLegacy SupportOther Microsoft SolutionsPower Platform ConsultantsAzure ConsultantsAzure Developers

- Industries

- Our Company

About Us

About UsLearn more about our HireDynamicsDevelopers portal and the team behind it.

Case StudiesRead successful stories from our clients across various industries.

ServicesFind the right service according to your specific business needs.

- Resources

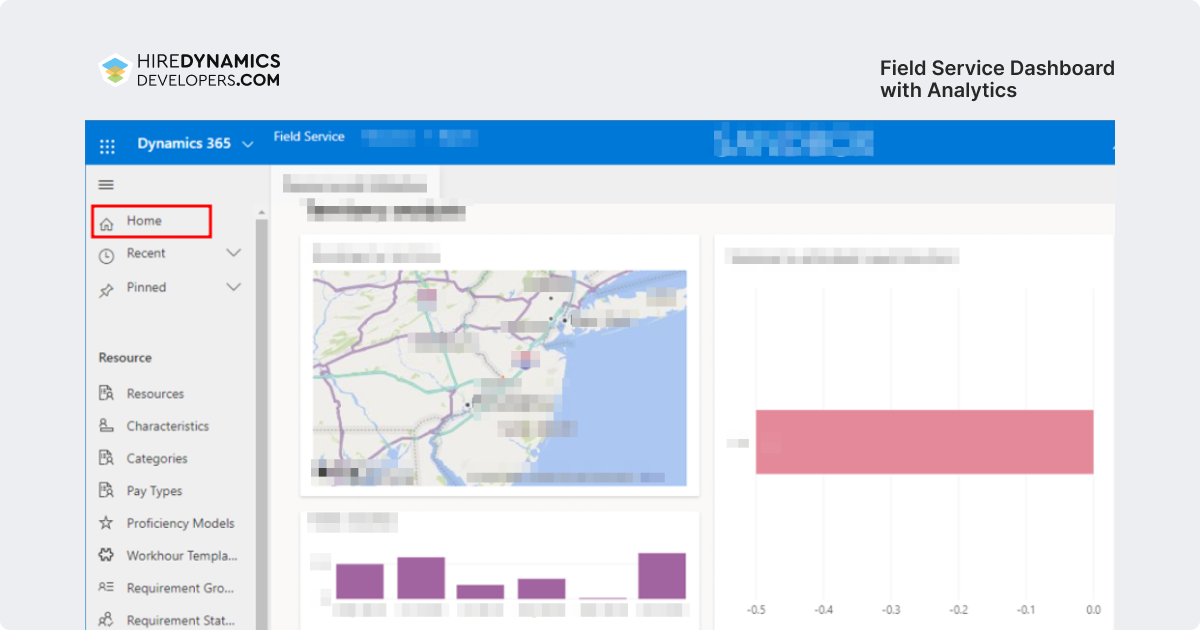

Optimizing Field Service Inventory Management with Dynamics 365

Published: January 10th, 2025 by Ivan Farafonov

Managing spare parts, tools, and equipment in field service can be really tough. Without accurate tracking and proper allocation, service technicians can face delays, and customers may experience service disruptions. This can result in poor customer satisfaction, increased operational costs, and missed revenue opportunities. That’s where Dynamics 365 Field Service comes in. It offers a comprehensive solution designed to streamline inventory management and enhance the efficiency of field service operations. This article discusses the challenges in field service inventory management and how Dynamics 365 can effectively address these issues.

Challenges in Field Service Inventory Management

Field service firms often run into some tough challenges dealing with inventory management operations. These challenges can have severe consequences, affecting not only internal operations but also customer service. Below are some of the most common issues:

Inventory visibility in Real-Time

Problems | Why It Matters |

|---|---|

| If you can’t see what’s in stock at all times, it causes chaos. Techs might reach job sites and discover they don’t have the right parts. This means they might have to come back later. This highlights the need for field service inventory management systems that provide up-to-date inventory data. |

Poor Stock Distribution

| When inventory isn’t organized, techs may have to drive back to central warehouses or regional hubs to get parts. This wastes time and energy. These issues can lead to higher costs and unhappy customers. |

Sticking to Manual Inventory Tracking

| Relying on these old ways makes it easy to mess things up. Mistakes happen often. This can make processes slow and can lead to higher labor costs. Businesses lose out if they don’t keep track of what’s used or when to restock. To streamline these operations, companies need inventory management software for field service that automates many of these tasks. |

Running Out of Parts or Having Too Many

| Stockouts lead to delays in service fulfillment and can leave customers unsatisfied. Overstocking ties up capital in inventory that isn’t used efficiently, increasing storage and procurement costs. By leveraging field service inventory management with Dynamics 365, companies can automate demand forecasting and reduce these issues. |

Struggling with Mobile Inventory Tracking

| When you can't track inventory on-the-go, you might face shortages or delays. This lack of visibility can lead to parts shortages, delays, and inaccurate inventory records. Field service software with inventory management addresses this problem by enabling mobile access to inventory journals and real-time updates. |

Poor Linking Inventory with Work Orders

| If work orders and inventory systems aren’t linked, it increases the chance of overlap or backtracking. This can make customers dissatisfied because the work isn’t completed on time. Field service inventory management in Dynamics 365 ensures that the system is seamlessly integrated with work orders. |

Struggling with Forecasting and Planning

| If you can’t predict what people need, you might run out of stock when demand is high. Or, you could end up with stuff nobody wants. D365 field service inventory management uses smart forecasting tools to help figure out what’s needed. |

Difficulty with Returns

| If returns aren't managed properly, things can get messy. When there's no clear process, broken items can stack up. This wastes time and causes more problems.Microsoft Dynamics field service inventory management solution has tools built-in to make returns easier. |

Communication Problems

| When communication is off, techs might miss updates about what’s available. This can delay service and upset customers. Proper inventory management tools can ensure everyone stays in the loop. Field service inventory management systems with real-time updates and mobile access ensure better communication across teams. |

Inconsistent Service Quality

| If the service isn't good, customers lose trust. That can mean losing part of your customer's and worse relations with your business. When there's a strong inventory setup, techs get what they need. This helps them give great service. Field service inventory management optimization ensures that service technicians have the right parts at the right time, resulting in improved service quality and customer loyalty. |

Hire our Field Service experts to implement all the features for your business!

How Dynamics 365 Field Service Addresses These Challenges

With Dynamics 365 Field Service, you can handle many of these problems easily. Automation helps a lot. Real-time data integration and better forecasting tools make things smoother, too. Here’s how D365 field service inventory management streamlines inventory management operations and improves field service operations.

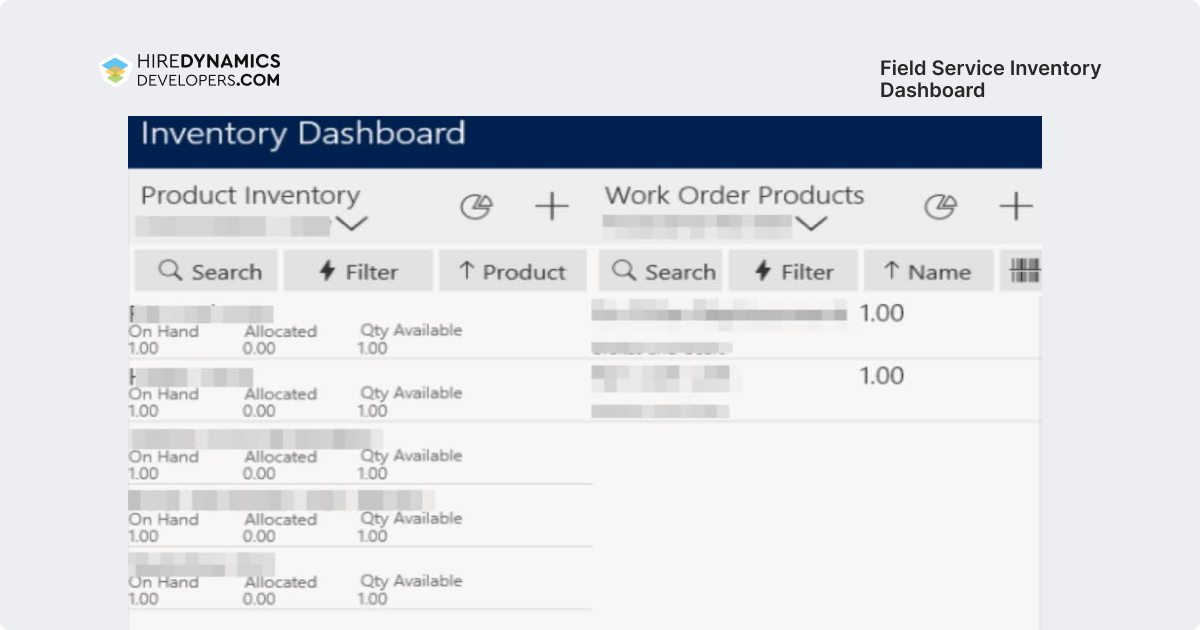

Up-to-Date Inventory Tracking

This feature helps businesses keep track of their inventory in different locations. It cuts down on running out of stock and having too much of it. Field technicians can check what parts are available right away. This makes sure they have what they need when they get to a job site, so they can fix things on the first visit.

Benefits:

- Provides an up-to-date view of inventory levels across all locations, including central warehouses, service vehicles, and field sites.

- Keep an eye on what you use and what’s in stock right away. This helps make sure everything is accurate and ready when you need it.

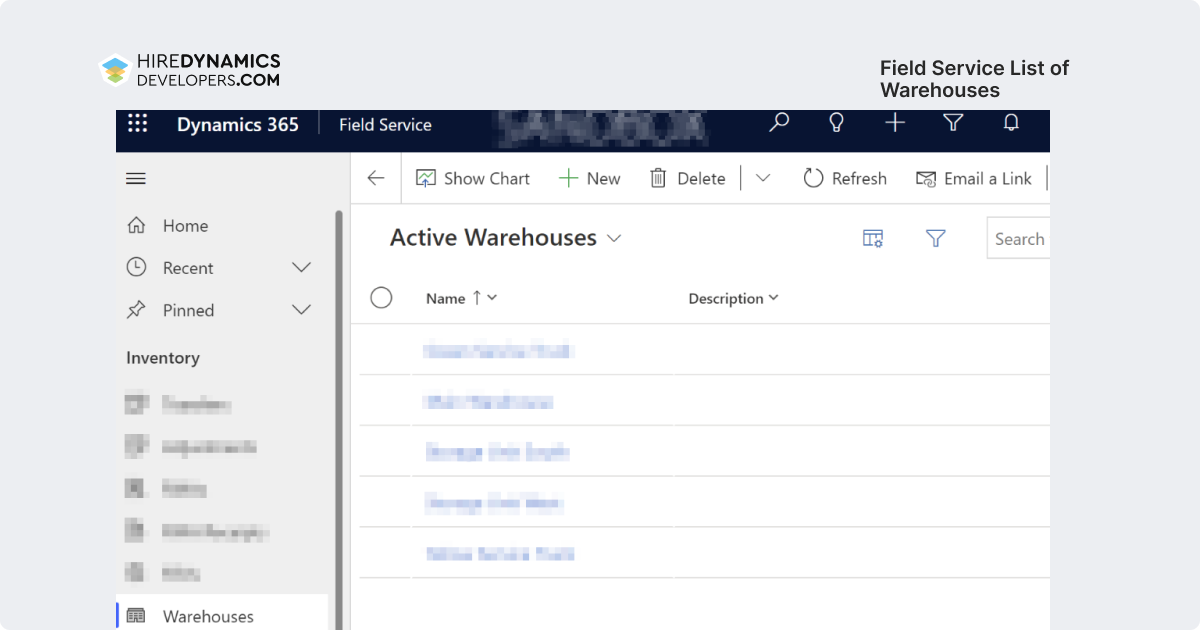

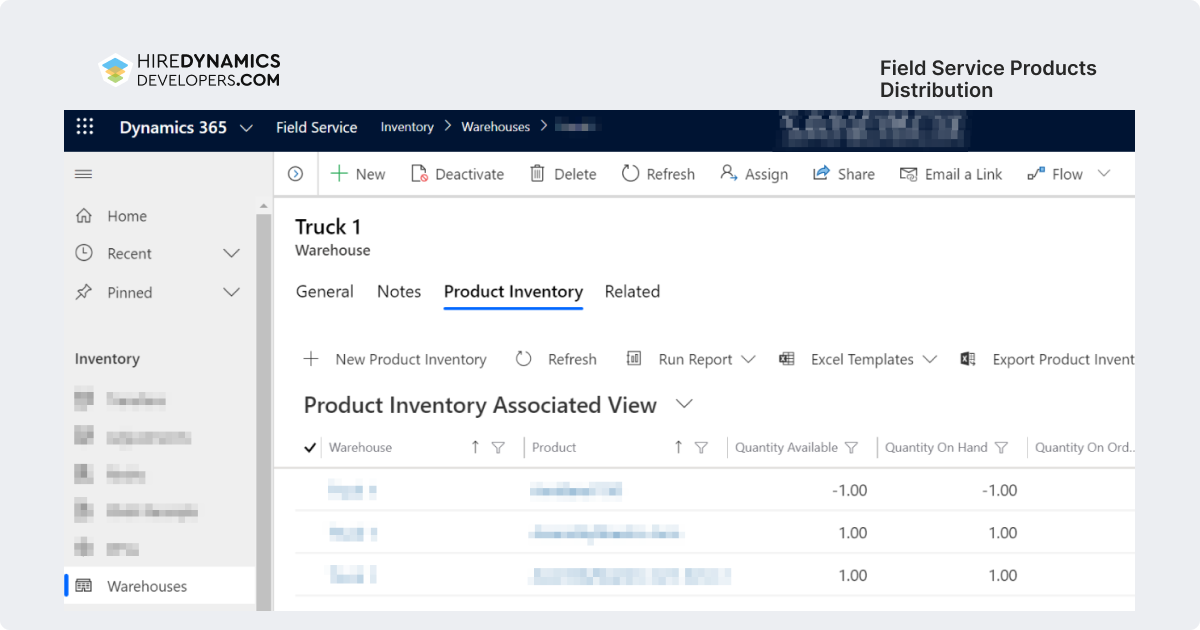

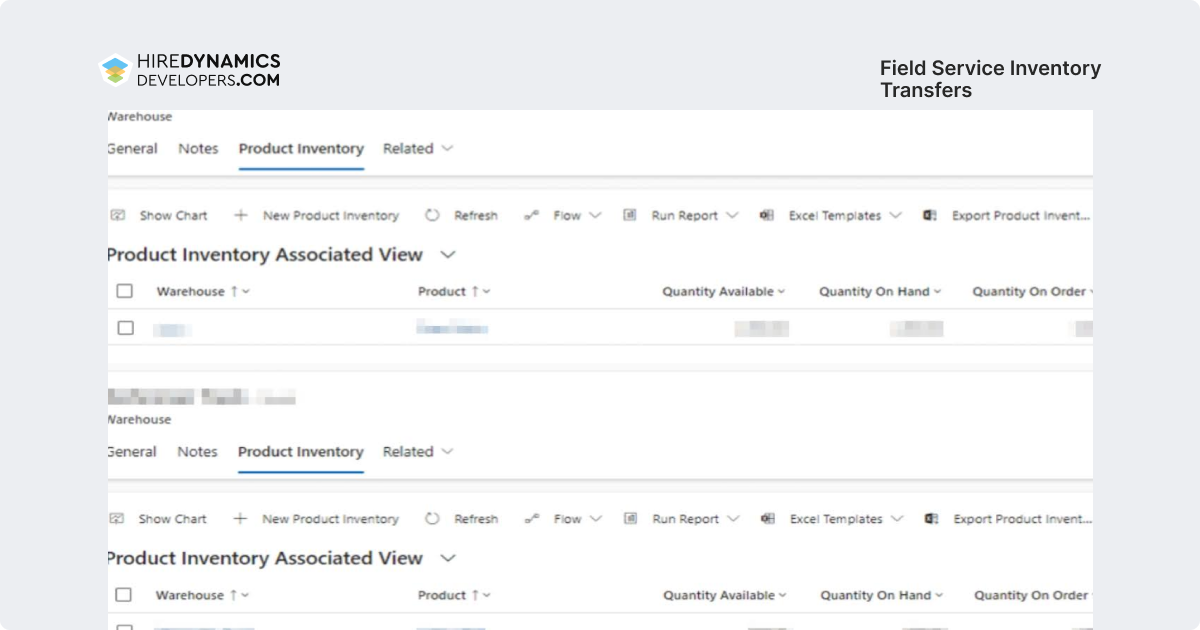

Managing Inventory Across Locations

Multi-location management helps businesses optimize company inventory and reduce the time field technicians spend searching for parts. This makes sure that technicians always have the parts they need. It also stops stockouts from hurting service performance.

Top Benefits:

- Manages inventory across various locations such as central warehouses, regional hubs, and mobile service vehicles.

- Supports real-time inventory transfers between locations, ensuring quick redistribution of parts when needed.

A real standout in optimizing Field Service Inventory Management with Dynamics 365 is the ability to track parts in transit between locations — not just from warehouse to technician, but between technicians in the field. I’ve seen this feature solve a major problem for a company where field staff were regularly running out of parts mid-job. Instead of returning to a warehouse, they used mobile transfer requests to get parts from nearby technicians, cutting downtime and improving first-time fix rates without increasing stock levels.

Microsoft D365 Technical Solution Architect

Connecting Inventory to Work Orders

This integration ensures that parts are available for scheduled work orders, increasing first-time fix rates and minimizing service delays. When inventory is tied to work orders, there is less risk of dispatching technicians without the necessary parts, improving customer satisfaction.

Top Benefits:

- Links inventory directly with work orders, ensuring required parts are allocated for specific tasks.

- Automatically reserves inventory for scheduled jobs, preventing over-commitment.

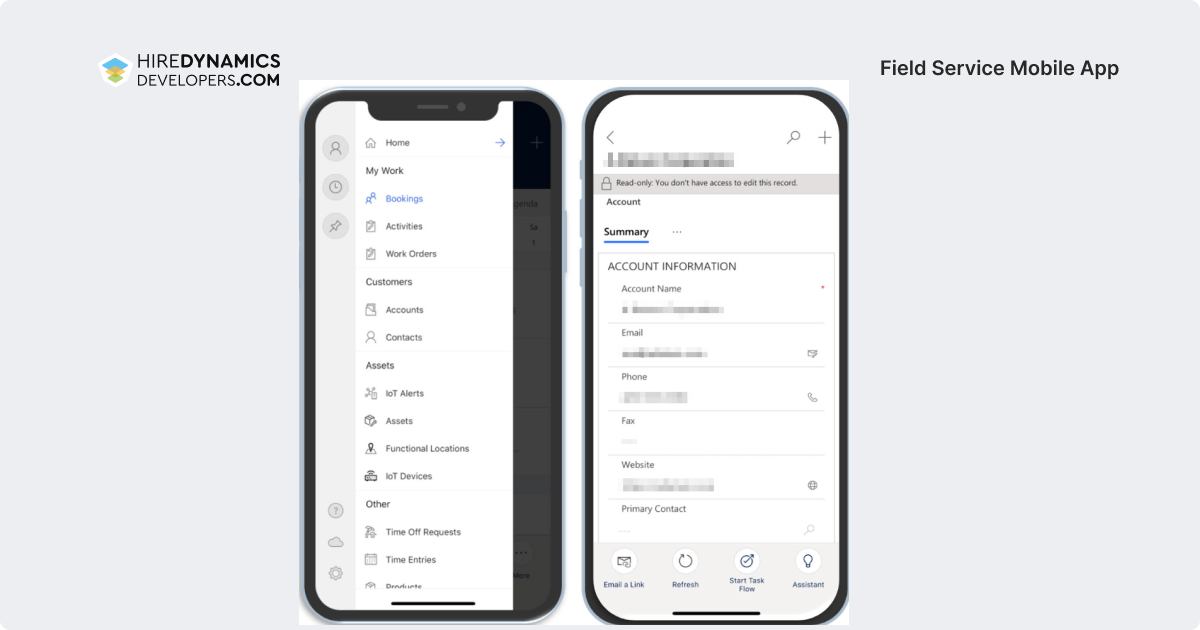

Mobile Inventory Management

With mobile inventory management, techs can keep an eye on stock. This helps them change stock levels and ask for more parts whenever they need them. This feature enhances real-time communication and improves accuracy in inventory journals and reporting.

Top Benefits:

- Field techs can check inventory data right on their mobile devices while they’re working.

- Allows technicians to log what parts they use, return, or adjust without any delays.

Automatic Replenishment

Automated replenishment ensures that companies maintain optimal stock levels without over-ordering, reducing procurement costs and minimizing stockouts. This feature helps businesses stay ahead of demand and improves inventory turnover rates.

Top Benefits:

- Monitors stock levels and automatically triggers replenishment when levels drop below predefined thresholds.

- Uses historical usage data and demand forecasting to optimize stock levels.

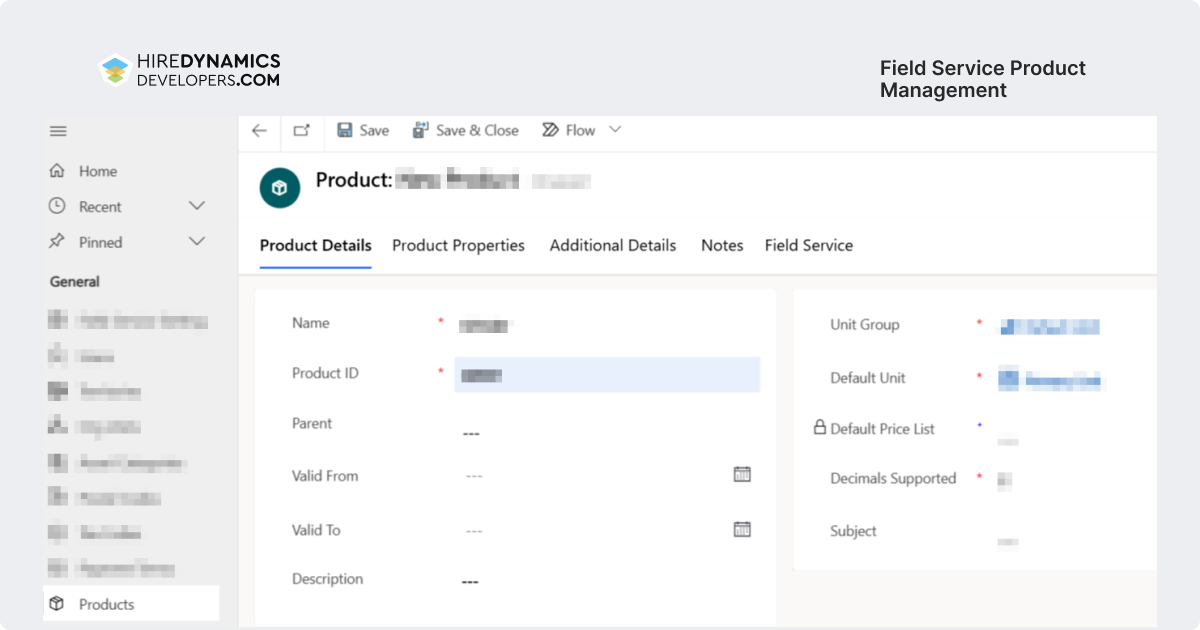

Serial Tracking

Lot and serial number tracking helps businesses keep an eye on their valuable inventory. This way, they can find out where items are, cut down on losses, and follow the rules in their industry. This feature is crucial for businesses that need to maintain stringent quality control standards.

Top Benefits:

- Tracks inventory by lot or serial number for enhanced traceability.

- Facilitates warranty tracking and industry compliance.

Forecasting and Planning Automation

This smart feature allows businesses to keep just the right amount of inventory. It helps prevent having too much or too little stock. Automating the ordering process also helps with cash flow and cuts storage costs.

Top Benefits:

- Dynamics 365 helps manage inventory by keeping an eye on stock levels. It can make purchase orders automatically when items are low.

- It also uses AI to forecast how much stock is needed. It looks at past sales and seasonal patterns.

Keeping Losses in Check

By watching inventory levels in real time and keeping detailed logs, businesses can cut down on losses from theft, mistakes, or lost items. This tracking adds more transparency and responsibility to inventory management operations.

Benefits:

- It tracks inventory with clear records of movements and transactions.

- You can also track lots and serial numbers for better control.

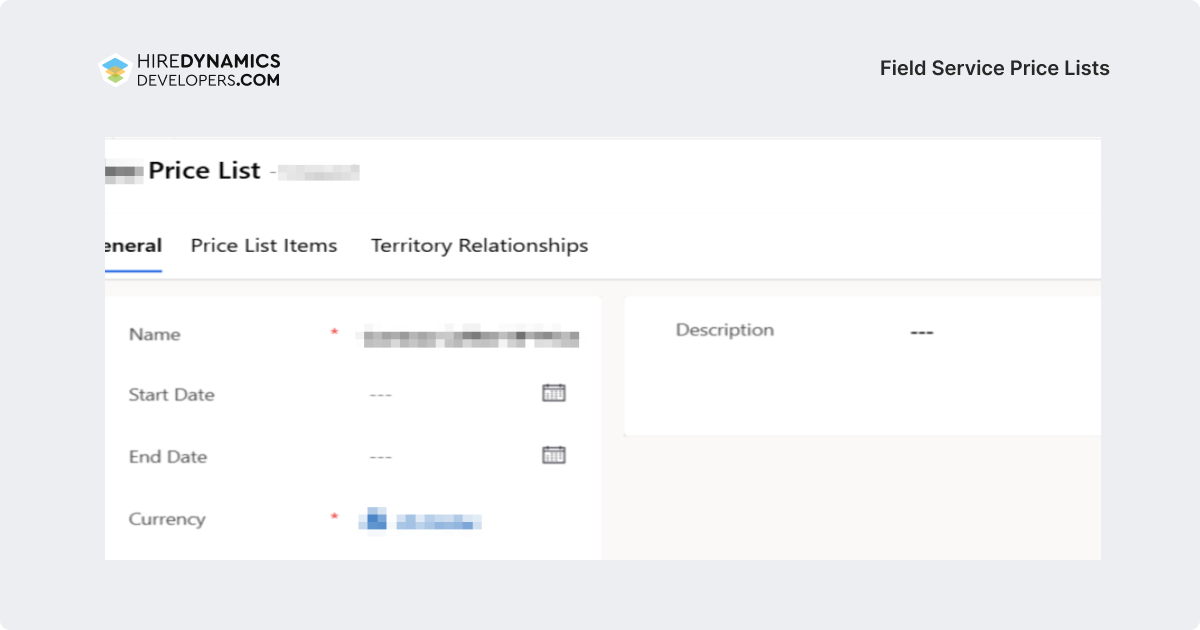

Managing Costs

Cost management tools in Dynamics 365 allow businesses to identify excess inventory, optimize ordering practices, and reduce the cost of carrying unnecessary stock. These features help to streamline operations and maximize profitability.

Top Benefits:

- Provides insights into inventory costs, turnover rates, and overstocking.

- Helps businesses identify and reduce unnecessary stock.

Returns Handling Made Easy

Dynamics 365 streamlines the returns process, helping companies quickly process and restock returned inventory. Efficient returns management reduces waste and ensures that only viable parts remain in the inventory.

Benefits:

- Manages returns by tracking unused or defective parts.

- Simplifies restocking or disposal of returned inventory items.

Our Successful Case Study

- USA

- HVAC

- Part-time Engagement

-

1 Dynamics Developer

1 Dynamics Consultant - Microsoft Dynamics 365 Field Service

Our client, a leading HVAC service provider in Northern California, specializes in air conditioning, heating, and indoor air quality solutions for homeowners and property managers. Facing inefficiencies caused by excessive paperwork and manual processes, they approached us to optimize their operations and improve service delivery.

After understanding their requirements, we identified Microsoft Dynamics 365 Field Service as the ideal solution and sourced the right experts—a Dynamics Developer and a Dynamics Consultant. The experts customized the platform to automate scheduling, improve real-time technician tracking, and integrate accounting workflows.

With optimized operations and a scalable system in place, the company is now well-equipped to handle growing demand while maintaining a high standard of customer satisfaction.

Streamlining Audits

The audit tools in Dynamics 365 help businesses maintain accurate inventory records, ensuring that physical stock matches system data. This reduces errors and increases inventory accuracy. All required inventory transactions and records can be created and tracked to see all movements and adjustments.

Benefits:

- Simplifies inventory reconciliation with audit and adjustment tools.

- Allows businesses to correct discrepancies in stock levels and system records.

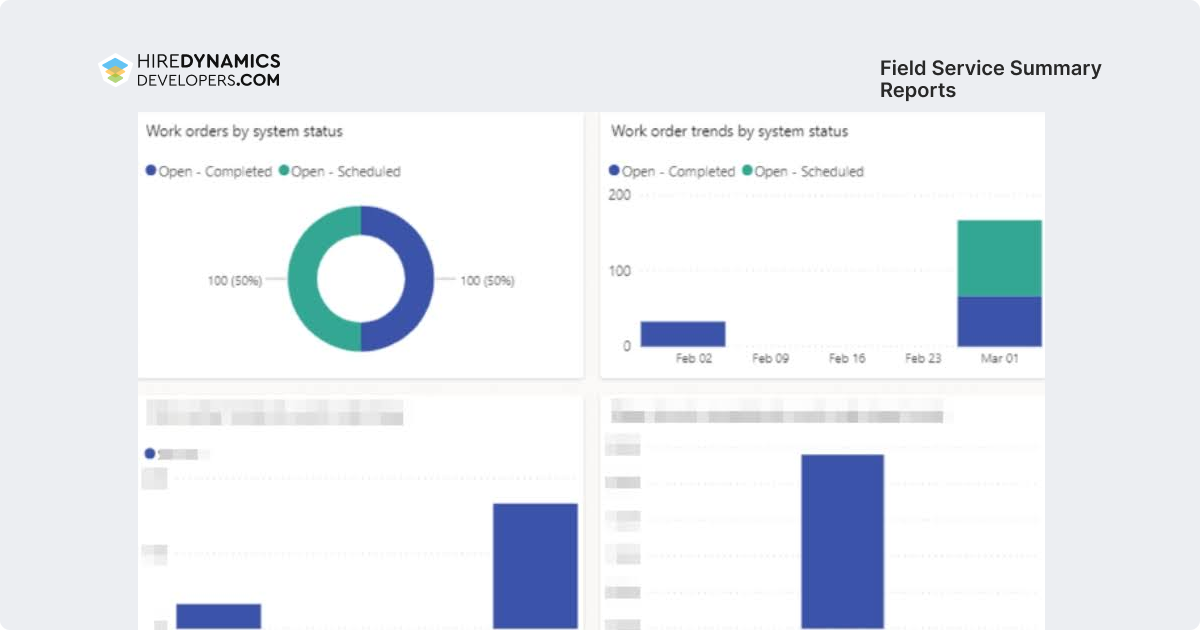

Better Reporting and Insights

Advanced reporting tools in Dynamics 365 help businesses track inventory performance, identify bottlenecks, and make informed decisions to improve operational efficiency. All reports can be customized to provide all required information and meet all company needs.

Benefits:

- Provides real-time reporting on inventory metrics such as turnover rates and shrinkage.

- Uses AI-driven analytics to provide insights that optimize inventory management.

Enhancing Customer Experience

By ensuring that technicians have the right parts and tools when they arrive on-site, Dynamics 365 enhances customer satisfaction and improves service reliability. All customers’ orders will be finished in precise time limits and raise the trust level of customers. Also, all calculations of costs and materials will be provided much faster.

Benefits:

- Ensures that technicians are always equipped with the right parts.

- Reduces service delays and improves first-time fix rates.

How Can HireDynamicsDevelopers Help You?

Dynamics 365 is a fairly complex system, which is why companies need the assistance of specialists to set it up properly. Experts help you not only install the module: they fully adapt the functionality to your needs and offer a customized solution for your business. There is only one problem: where to find a skilled and reliable assistant? This is where we can help.

HireDynamicsDevelopers has a large database of consultants on various Microsoft solutions and helps with all stages of hiring. So, with minimal effort, you get reliable reinforcement to your team and work professionally with the necessary modules. Simply share your needs and problems, and we will find the right Dynamics 365 Field Service specialist. Try it and see for yourself!

Some of our Dynamics Consultants

Conclusion

Optimizing field service inventory management is a vital aspect of field service operations. Dynamics 365 Field Service offers a comprehensive solution to address challenges such as stockouts, overstocking, inefficient allocation, and poor communication. By automating inventory management operations, providing real-time data visibility, and integrating seamlessly with work orders, Dynamics 365 helps businesses improve operational efficiency and customer service. Dynamics 365 has great tools for predicting needs and managing tasks on the go. This helps field service companies provide quick and dependable service. Happy customers mean more business.

It also makes handling inventory much easier. It cuts costs and makes sure that technicians have the right parts when they need them. This changes the game for how field service teams manage inventory and their supplies. This ultimately results in faster service delivery, reduced downtime, and enhanced customer loyalty. The field service industry is always changing. Tools like Dynamics 365 field service inventory management will be key for businesses. They help companies keep up with the competition.

Are you looking to optimize Dynamics 365 for field service?

Contact us to find reliable consultants!

Outline

Tatyana S.

40 HOURS / WEEK

Alexander S.

40 HOURS / WEEK

Franka M.

10 HOURS / WEEK

Request Our Services

Optimize Field Service Operations with Dynamics 365 with Our Experts!

Your Partner Recognized in Dynamics Community